In manufacturing, the quality of fasteners is a top priority. These small components are used in everything from cars to airplanes, and even the smallest defect—like a crack, a misaligned thread, or a surface flaw—can cause major problems. This is where vision inspection systems come in; they offer a dependable way to make sure every fastener meets quality standards.

Mectron’s Inspection Approach

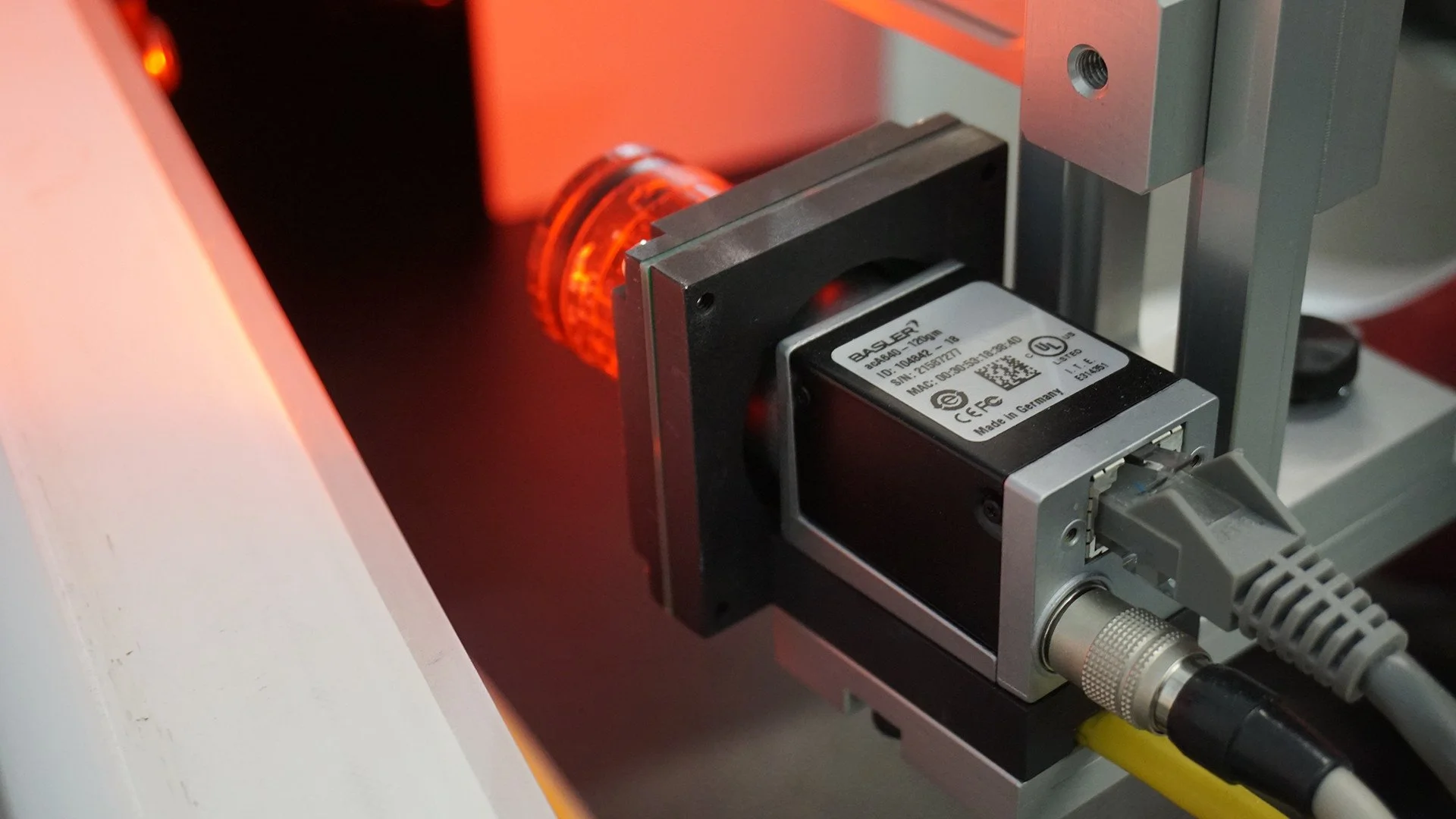

Mectron’s inspection technologies, including their vision inspection systems, are made to handle these challenges. By combining laser, eddy current, and vision-based methods, Mectron provides a complete solution for finding defects in fasteners. Vision inspection, in particular, is great at spotting surface issues that other methods might miss. For example, it can detect open burst cracks, recess imperfections, and through-hole defects using high-resolution cameras. This ensures that every fastener is checked thoroughly before it’s used in production.

Combining Vision Inspection with Eddy Current Technology

One of the best features of Mectron’s vision inspection systems is how well they work with other technologies, like the RCD-9500 Rotary Crack Detection system. The RCD-9500 uses a differential eddy current probe to find cracks and other internal flaws in fasteners. When paired with vision inspection, the system becomes even more powerful. While the eddy current probe checks for internal issues, the vision system scans the surface for visible defects. This combination makes sure that both inside and outside problems are caught, giving a full picture of the fastener’s condition.

How the RCD-9500 Improves Inspection Accuracy

The RCD-9500 itself is an impressive piece of equipment. It uses motorized rollers to rotate the fastener in place, letting the eddy current probe scan the part multiple times for more accuracy. Optical sensors make sure parts are fed, scanned, and sorted automatically, reducing the chance of human error. The system’s modular design lets it handle various fastener types, from small ball studs to more significant flanged parts. When used with Mectron’s EC600 digital eddy current instrument, the RCD-9500 can inspect up to 180 parts per minute, making it one of the fastest systems available.

Flexibility for Different Applications

However, the benefits of vision inspection systems do more than just provide speed and accuracy. They’re also very adaptable. Mectron’s systems can be customized for different industries and applications. For instance, the SQ-7500 Surface Qualifier uses image processing to find surface defects like dents, scratches, and discoloration. Meanwhile, the DSQ-9000 combines surface and dimensional inspection for 360-degree coverage of each fastener.

Production Line Integration

Another advantage of Mectron’s vision inspection systems is their ability to combine with existing production lines. The Q-5000 Inspection System, for instance, uses eight lasers to perform 360-degree dimensional inspections. When paired with vision inspection, it can find thread defects, feature deviations, and foreign material with incredible precision. The system’s touchscreen interface makes it easy to program and adjust inspection settings, while its automated sorting feature offers only defect-free parts to move forward in production.

Safety and Reliability

In industries where safety and reliability are necessary, Mectron’s vision inspection systems provide confidence. By catching defects early, they help manufacturers avoid recalls, reduce waste, and maintain their quality reputation. Whether it’s a small crack in a fastener or a surface flaw that could affect performance, Mectron’s systems are built to find it.

Conclusion

Vision inspection systems are an important tool for fastener quality control. By combining technologies like laser scanning, eddy current detection, and high-resolution imaging, Mectron has created inspection systems that set the standard for precision and reliability. For manufacturers looking to make sure their fasteners are high in quality, Mectron’s solutions offer a proven way to meet these expectations.