eddy-current technology

EC600 leads the industry in accuracy for inspection

The Mectron EC600 is an all-digital eddy current instrument with specifically designed software for a diverse number of applications. It utilizes a touch screen display which allows for complete control of the impedance plane signature.

The eddy current’s signal is easily controlled on the system’s touch screen operator interface. The displayed eddy current signal can be manipulated to alter frequency, phase, horizontal gain and vertical gain as well as to set the high and low thresholds to detect the differences between good and defective products. The usable frequency range of the Mectron EC600 instrument is 35 Hz to 5 MHz. Using Opto 22 I/O modules, the EC600 can be configured to accept AC or DC inputs and output AC or DC to typical PLC’s or control relays.

The EC600 is equipped with a Digital Signal Processor and algorithms for passing only the frequencies above the user specified cut-off. This development is used to eliminate the effects of runout or varying lift-off that can occur in certain applications.

N-Series/HSb:

Inspect nuts, precision and plastic components at high speeds

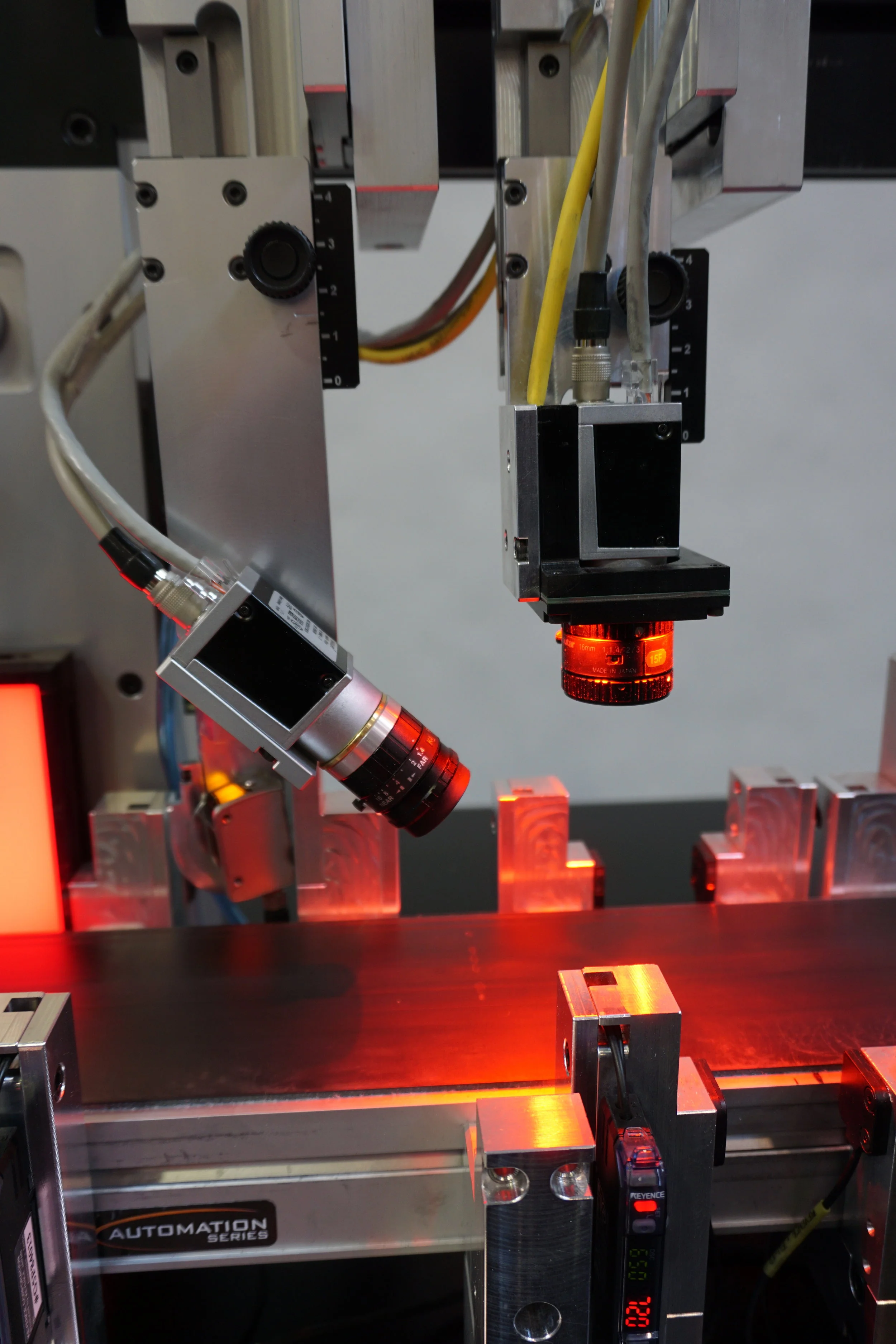

N-Series/HSB Machines utilize vision, digital eddy current, and lasers to inspect nuts, screw machine parts, precision components and plastic components.

HSB

Belt system that uses cameras for Internal Thread Detection, overall height, diameter and other dimensions

N-400

Flat track system for Internal Thread Detection Laser Unit with Digital Eddy Current and Vision System

N-350

Flat track system for Internal Thread Detection Laser Unit with Digital Eddy Current

N-300

Flat track system for Internal Thread Detection Laser Unit and Vision System

Automated packaging

The MAP2500 is an ergonomic design that delivers filled cartons to a waist level.

The MAP2500 features a power feed roller which supplies the unfilled cartons to the inspection gate chute. As product is inspected and accepted, the parts pass through the flipper gate and into the carton. This fully automatic operation allows the operator to set the piece count per carton on the system counter. Once the full carton is attained, the system shuttles the full carton over to the lift station, and brings in the next empty carton into the fill position. The counter is then automatically reset and the inspection cycle is repeated.

The full carton is lifted to a section of rollers that are at a 35″ (890 mm) height from the floor for ease of handling by the system operator. The integrated packaging is ideal for manufacturers who want to ensure exact piece count per carton, and guarantee that mixed parts aren’t introduced during an off line packaging method. By putting the part in the box immediately after inspection, the chance of introducing foreign material later is greatly decreased.

The addition of either packaging machines to any existing Mectron Inspection System provides the ultimate in turnkey operations.