Non-destructive testing (NDT) methods, such as eddy current inspection, are important tools in the manufacturing industry for quality control. Mectron’s eddy current machines are a solution that manufacturers can use to quickly and accurately identify defects without damaging tested components.

Eddy Current Inspection

Eddy current inspection is a nondestructive testing method that uses electromagnetic induction to detect surface and subsurface defects in conductive materials. When an alternating current passes through an inspection coil, it creates a magnetic field that produces eddy currents in the tested material. The flow of these currents is disrupted by any imperfections, such as cracks, material discrepancies, or hardness variations, triggering measurable changes that are detected by the system.

In industries where high-precision inspections are required, such as fastener manufacturing, ammunition production, and deep draw metal processing, this method is particularly effective. Eddy current inspection is unique for its high sensitivity to small imperfections, finding defects prior to the parts’ market release.

Eddy Current Machines of Mectron

Mectron’s eddy current machines feature technology and user-friendly features, providing fantastic inspection performance. For example, the MI8500 series uses Magnetic Imagery™, an advanced digital eddy current technique, to generate a complete magnetic signature of each part. This signature allows for:

Crack Detection: Identifying critical surface and subsurface cracks that may compromise product integrity.

Material Mix Identification: Distinguishing between various material compositions to prevent mix-ups.

Hardness Testing: Proper heat treatment and case depth to meet performance requirements.

Wire Seam and Induction Hardening Analysis: Pinpointing metallurgical defects that can affect long-term reliability.

In addition to metallurgical inspection, Mectron’s eddy current machines can sort parts for missing features, length variations, and gross defects—all while operating at high speeds. These systems deliver rapid, accurate results, streamlining quality control processes and minimizing downtime.

High-Speed Inspection for Demanding Applications

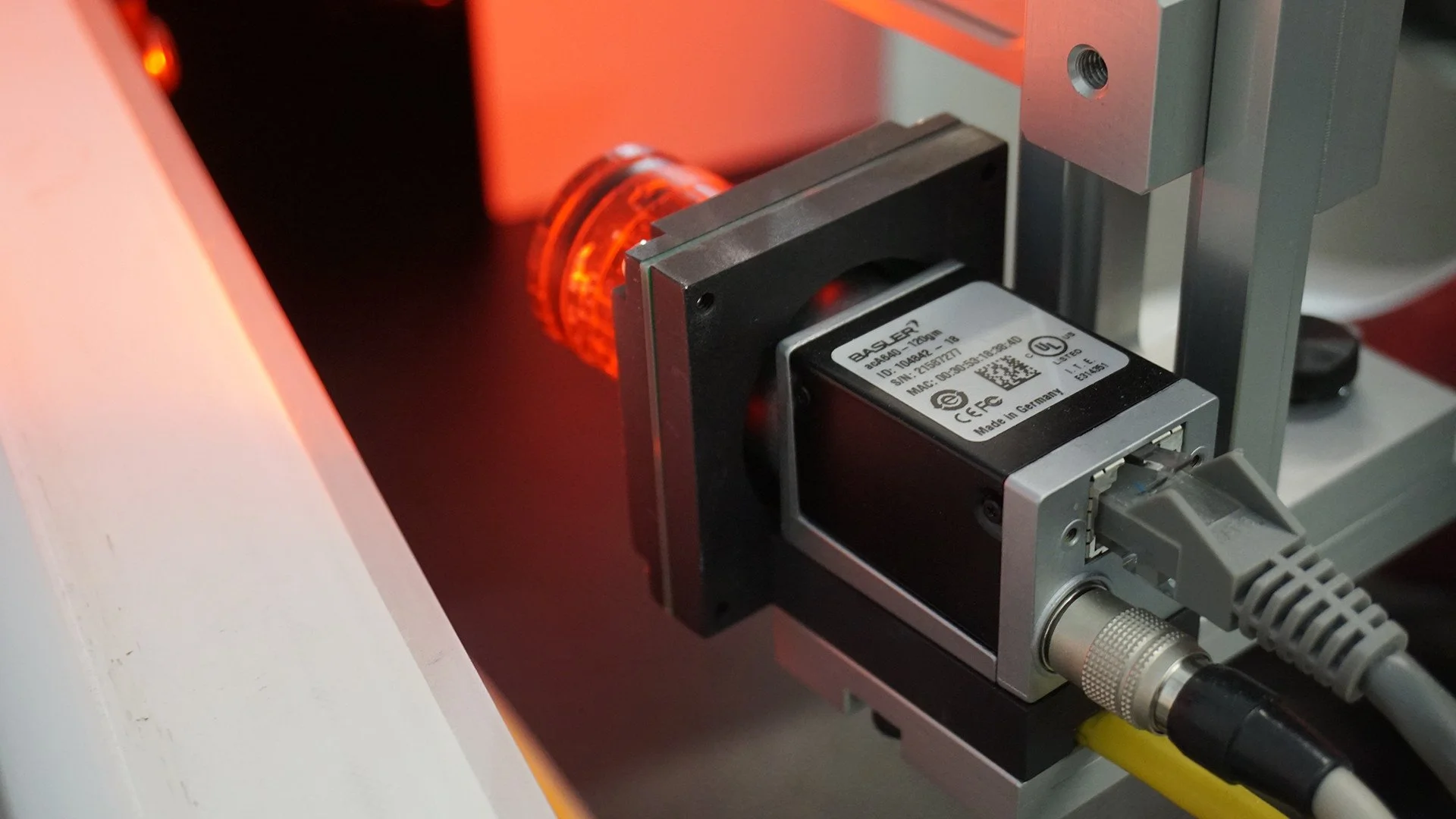

Mectron’s Q-Series machines integrate eddy current inspection with high-speed dimensional analysis to meet the needs of demanding applications. The Q-5000 system, for example, combines a 360° laser scan using up to eight lasers with digital eddy current inspection to provide the following:

Comprehensive 360° Analysis: Parts are inspected from every angle so that no defect goes unnoticed.

Rapid Results: High-speed inspection capabilities allow manufacturers to maintain production flow without compromising accuracy.

Flexible Sorting Options: Optional crack detection, CCD vision systems, and tilt plates provide customizable solutions for diverse inspection needs.

Whether inspecting fasteners, ammunition, or other precision components, Mectron’s systems deliver the most advanced inspection solutions on the market; they allow manufacturers to benefit from faster defect detection, reduced scrap rates, and improved product quality.

Advantages of Integrating Eddy Current Inspection

Applying Mectron’s eddy current machines into your quality control processes gives you the following advantages:

Non-Destructive Testing: Parts can be thoroughly inspected without any damage, preserving their usability and value.

High Sensitivity: Eddy current systems are capable of detecting the smallest defects, ensuring only flawless products proceed to the next stage.

Rapid Assessments: High-speed operation supports continuous production with very few interruptions.

Cost Efficiency: By identifying defects early, manufacturers can reduce waste, minimize rework, and lower overall production costs.

Versatility: Mectron’s eddy current machines can inspect a variety of materials and part types, making them suitable for diverse manufacturing applications.

Data-Driven Insights: Advanced systems like the MI8500 and Q-Series provide actionable feedback through real-time data, enabling continuous process improvements.

Why Choose Mectron’s Eddy Current Machines?

Mectron stands apart as an industry leader in non-destructive testing solutions. By combining eddy current inspection with advanced technologies, such as Magnetic Imagery™ and 360° laser scanning, their eddy current inspection provides remarkable accuracy and speed. Mectron’s inspection systems are easy to integrate into manufacturing environments, increasing efficiency and product reliability.

Mectron’s eddy current machines allow manufacturers to have peace of mind that their parts meet the most demanding quality standards. From fastener and ammunition inspections and beyond, Mectron’s solutions are precise and high-performing.

Conclusion

Eddy current inspection is a proven, non-destructive method facilitating product quality in manufacturing. Mectron’s advanced eddy current machines are unmatched in speed, sensitivity, and accuracy and are the perfect choice for manufacturers who want to optimize their quality control processes. Contact Mectron today to learn more about how these amazing machines can transform your end products.